ARLINGTON – Aerospace manufacturing is riding a wave of growth in Arlington and Marysville, and companies like Global Machine Works that invest in new technology and deliver “speed-to-market” efficiency are driving that activity.

From its humble start in 1998 as a small subcontract machining operation near Arlington Municipal Airport employing three workers, principal shareholders Brent Barker and Brad Stucynski have built a cutting edge company.

Barker, who designed propulsion systems for experimental aircraft at the airport, and Stucynski, a former Marine who became a machinist because of the hands-on fun of making things, bought the company where they worked and its single building to make GMW a thriving business.

Today, the company’s footprint has expanded to 54,000 square feet and five buildings, employing 102 people, with revenues in the millions.

“We’re the largest of the small shops in the area,” materials manager John Opel said.

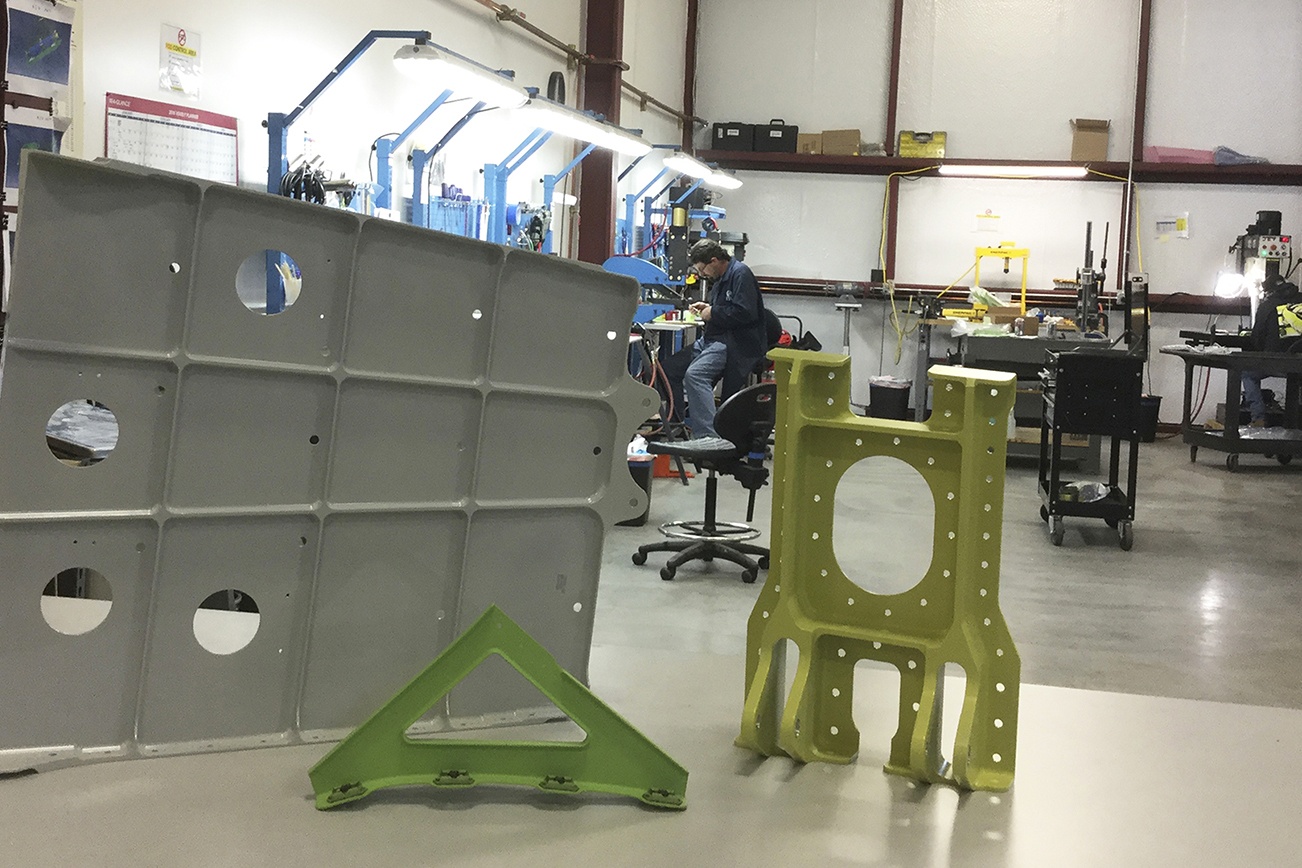

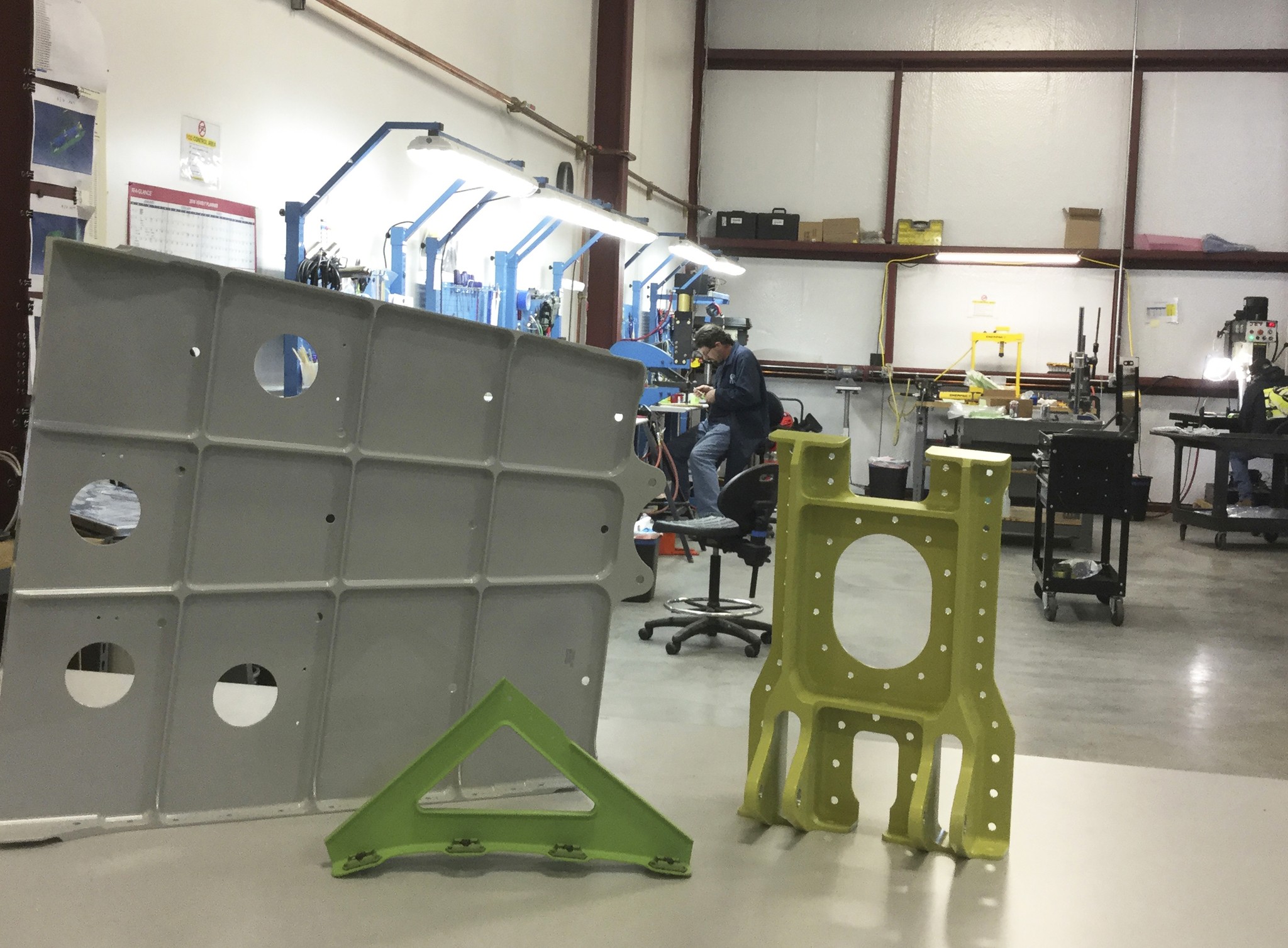

The company supplies components for Boeing’s 737 MAX, 777 and 787 Dreamliner, which constitutes the bulk of their business. GMW manufactures products from nose-to-tail to include structural control and interior components.

“We’re making parts for all the right birds,” Stucynski said.

Since 2010, the company has seen up to a 20 percent growth each year, and projections to 2020 see no let up, Opel said. Another development is that with the increased volume of work at Global, they have been able to sub-contract some work to smaller manufacturers.

GMW wasn’t a registered parts manufacturing contractor with Boeing until two years ago. But within two weeks of Opel applying, they had their first two contracts. Within weeks, they were supporting four Boeing sites in the U.S. and Canada, based on their precision and timely processing of parts orders. Now they have more than 200 parts and pieces in production.

Research shows that GMW will have work for the next six years. Boeing per month is rolling out forty-five 737-MAXs, seven 777s and twelve 787s. By 2023, output for the three lines could reach 100 airplanes.

Global is deploying new cell technology and advanced production techniques. While the upfront equipment investment runs in the millions, the machines pay themselves off in volume of parts manufactured, and turnaround time, both key in an industry where the customer wants it now.

They have a continuous loading cell system. It’s an automated work of art in progress; the key is the fewer number of setups needed for workers to have to change out the product, the better and more efficient.

Here’s an overview of how the system works, from mill to finished part:

Once the blocks of aluminum or other raw heavy metal arrives at Global, the job is labelled and taken to one of their machining centers.

GMW uses cell technology that gives them the ability to run the part “lights out,” meaning that once the last crew leaves at midnight, the machines continue to run until 5:30 the next morning when the next crew comes in to remove the parts.

Global purchased Grob 550 5-axis milling machines. Five-axis cutters are used to machine components with extremely complex contours and configurations out of a single piece of metal. The $1 million units are top of the line. When a palatte enters the G550, the cutter engages the material and starts machining to precise specifications around all sides of the part.

The finished machine part comes off the machine, a mere fraction of itself, probably 85 percent material removal. At that point, it’s ready to be painted, put into a finished module, or an assembly right on the aircraft itself.

“From a customer standpoint, what we’re most noted for is speed-to-market,” Opal said.

When the parts are finished, Global uses a unique vertical system for storing, accessing and organizing parts. Space comes at a premium, so with these units, parts can be stored and organized for shipping in a vertical, automated rotating drawers fashion. A digital readout at waist level on the compartments show the part, order number, who is getting them, and other information. The company now has three. Where one horizontal system would typically take up 900 feet of floor space, each one of their units needs only 100 square feet, freeing up space for other needs.

GMW has remained privately held, and that has yielded benefits at during a time where similar companies have been sold to larger ones, Opel said. When Global wants to buy new equipment, they can simply order it. With larger companies, the process can run through levels of management.

There is one product line belonging to Global Machine Works that no other aerospace manufacturing company can compete: they make high-end signature brass saxophone mouth pieces for Claude Lakey Woodwinds. It’s a throwback to their fledging days in the machine shop, when they turned out a half dozen then compared to the hundreds they complete now. They continue to manufacture them as the only non-aerospace part at the company.

Global works with local schools and educators to let local students know that their company and others are going to need machinists and other works to operate their high-tech equipment, and wages can start at $25 an hour. They have also connected with AMTEC North at Weston High School, which has an upstart machining program tied to the flagship Advanced Manufacturing Training & Education Center at Everett Community College. The company gives student tours of their operation to help dispel the myth that machining is a greasy, grimy job.

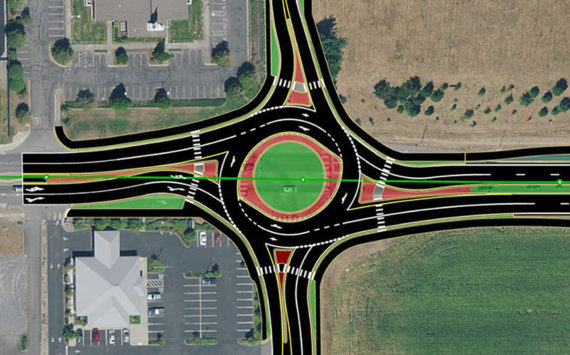

The growth of businesses like GMW is great news for Marysville and Arlington leaders, who worked doggedly to establish a Manufacturing Industrial Center that brings more capital investment, economic development and skilled living wage jobs to the Arlington Airport and industrial-zoned land in Marysville south of the airport.

“Many years ago, if you had the right skills, you headed south and were willing to make the move,” Stucynski said. “That’s not the case any more.”